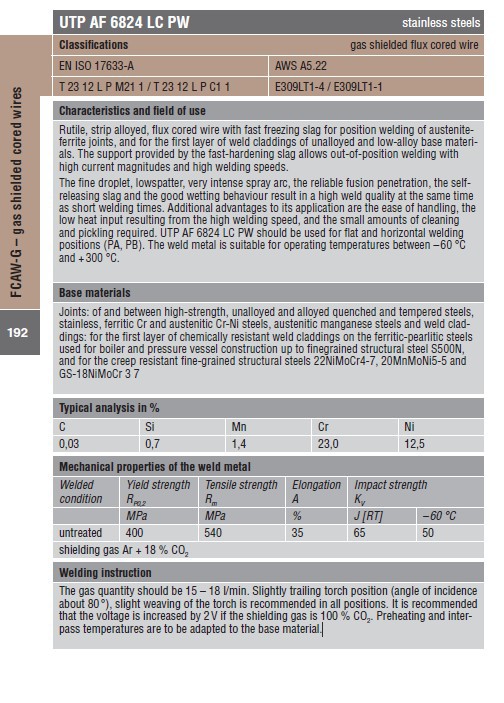

UTP AF 6824 LC PW stainless steels

Classifications gas shielded flux cored wire

EN ISO 17633-A AWS A5.22

T 23 12 L P M21 1 / T 23 12 L P C1 1 E309LT1-4 / E309LT1-1

Characteristics and field of use

Rutile, strip alloyed, flux cored wire with fast freezing slag for position welding of austeniteferrite

joints, and for the first layer of weld claddings of unalloyed and low-alloy base materials.

The support provided by the fast-hardening slag allows out-of-position welding with

high current magnitudes and high welding speeds.

The fine droplet, lowspatter, very intense spray arc, the reliable fusion penetration, the selfreleasing

slag and the good wetting behaviour result in a high weld quality at the same time

as short welding times. Additional advantages to its application are the ease of handling, the

low heat input resulting from the high welding speed, and the small amounts of cleaning

and pickling required. UTP AF 6824 LC PW should be used for flat and horizontal welding

positions (PA, PB). The weld metal is suitable for operating temperatures between – 60 °C

and + 300 °C.

Base materials

Joints: of and between high-strength, unalloyed and alloyed quenched and tempered steels,

stainless, ferritic Cr and austenitic Cr-Ni steels, austenitic manganese steels and weld claddings:

for the first layer of chemically resistant weld claddings on the ferritic-pearlitic steels

used for boiler and pressure vessel construction up to finegrained structural steel S500N,

and for the creep resistant fine-grained structural steels 22NiMoCr4-7, 20MnMoNi5-5 and

GS-18NiMoCr 3 7

Typical analysis in %

C Si Mn Cr Ni

0,03 0,7 1,4 23,0 12,5

Mechanical properties of the weld metal

Welded

condition

Yield strength

RP0,2

Tensile strength

Rm

Elongation

A

Impact strength

KV

MPa MPa % J [RT] – 60 °C

untreated 400 540 35 65 50

shielding gas Ar + 18 % CO2

Welding instruction

The gas quantity should be 15 – 18 l/min. Slightly trailing torch position (angle of incidence

about 80 °), slight weaving of the torch is recommended in all positions. It is recommended

that the voltage is increased by 2 V if the shielding gas is 100 % CO2. Preheating and interpass

temperatures are to be adapted to the base material.

![]() 暂无相关下载

暂无相关下载