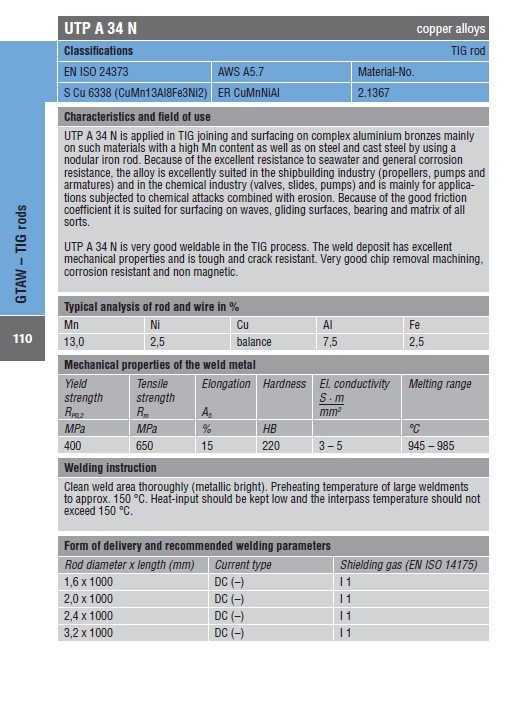

UTP A 34 N copper alloys

Classifications TIG rod

EN ISO 24373 AWS A5.7 Material-No.

S Cu 6338 (CuMn13Al8Fe3Ni2) ER CuMnNiAl 2.1367

Characteristics and field of use

UTP A 34 N is applied in TIG joining and surfacing on complex aluminium bronzes mainly

on such materials with a high Mn content as well as on steel and cast steel by using a

nodular iron rod. Because of the excellent resistance to seawater and general corrosion

resistance, the alloy is excellently suited in the shipbuilding industry (propellers, pumps and

armatures) and in the chemical industry (valves, slides, pumps) and is mainly for applications

subjected to chemical attacks combined with erosion. Because of the good friction

coefficient it is suited for surfacing on waves, gliding surfaces, bearing and matrix of all

sorts.

UTP A 34 N is very good weldable in the TIG process. The weld deposit has excellent

mechanical properties and is tough and crack resistant. Very good chip removal machining,

corrosion resistant and non magnetic.

Typical analysis of rod and wire in %

Mn Ni Cu Al Fe

13,0 2,5 balance 7,5 2,5

Mechanical properties of the weld metal

Yield

strength

RP0,2

Tensile

strength

Rm

Elongation

A5

Hardness El. conductivity

S · m

mm2

Melting range

MPa MPa % HB °C

400 650 15 220 3 – 5 945 – 985

Welding instruction

Clean weld area thoroughly (metallic bright). Preheating temperature of large weldments

to approx. 150 °C. Heat-input should be kept low and the interpass temperature should not

exceed 150 °C.

Form of delivery and recommended welding parameters

Rod diameter x length (mm) Current type Shielding gas (EN ISO 14175)

1,6 x 1000 DC (–) I 1

2,0 x 1000 DC (–) I 1

2,4 x 1000 DC (–) I 1

3,2 x 1000 DC (–) I 1

![]() 暂无相关下载

暂无相关下载