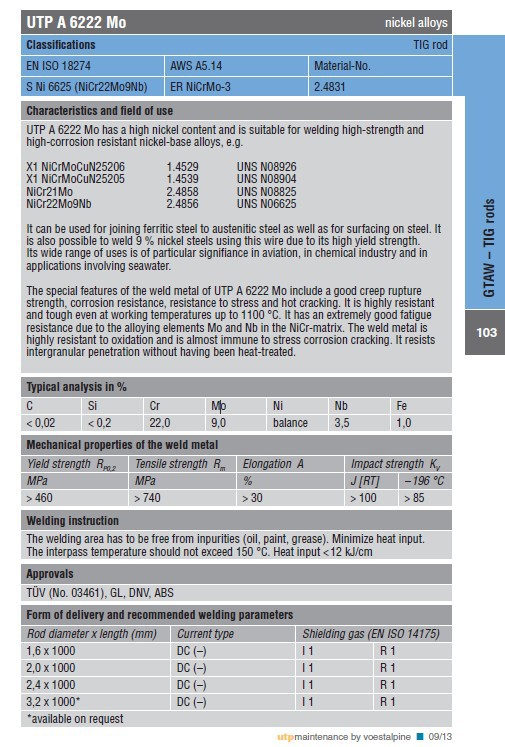

UTP A 6222 Mo nickel alloys

Classifications TIG rod

EN ISO 18274 AWS A5.14 Material-No.

S Ni 6625 (NiCr22Mo9Nb) ER NiCrMo-3 2.4831

Characteristics and field of use

UTP A 6222 Mo has a high nickel content and is suitable for welding high-strength and

high-corrosion resistant nickel-base alloys, e.g.

X1 NiCrMoCuN25206 1.4529 UNS N08926

X1 NiCrMoCuN25205 1.4539 UNS N08904

NiCr21Mo 2.4858 UNS N08825

NiCr22Mo9Nb 2.4856 UNS N06625

It can be used for joining ferritic steel to austenitic steel as well as for surfacing on steel. It

is also possible to weld 9 % nickel steels using this wire due to its high yield strength.

Its wide range of uses is of particular signifiance in aviation, in chemical industry and in

applications involving seawater.

The special features of the weld metal of UTP A 6222 Mo include a good creep rupture

strength, corrosion resistance, resistance to stress and hot cracking. It is highly resistant

and tough even at working temperatures up to 1100 °C. It has an extremely good fatigue

resistance due to the alloying elements Mo and Nb in the NiCr-matrix. The weld metal is

highly resistant to oxidation and is almost immune to stress corrosion cracking. It resists

intergranular penetration without having been heat-treated.

Typical analysis in %

C Si Cr Mo Ni Nb Fe

< 0,02 < 0,2 22,0 9,0 balance 3,5 1,0

Mechanical properties of the weld metal

Yield strength RP0,2 Tensile strength Rm Elongation A Impact strength KV

MPa MPa % J [RT] – 196 °C

> 460 > 740 > 30 > 100 > 85

Welding instruction

The welding area has to be free from inpurities (oil, paint, grease). Minimize heat input.

The interpass temperature should not exceed 150 °C. Heat input < 12 kJ/cm

Approvals

TÜV (No. 03461), GL, DNV, ABS

Form of delivery and recommended welding parameters

Rod diameter x length (mm) Current type Shielding gas (EN ISO 14175)

1,6 x 1000 DC (–) I 1 R 1

2,0 x 1000 DC (–) I 1 R 1

2,4 x 1000 DC (–) I 1 R 1

3,2 x 1000* DC (–) I 1 R 1

*available on request

![]() 暂无相关下载

暂无相关下载