| 详细介绍:

备注:一口价为1公斤的价格!20公斤/箱!

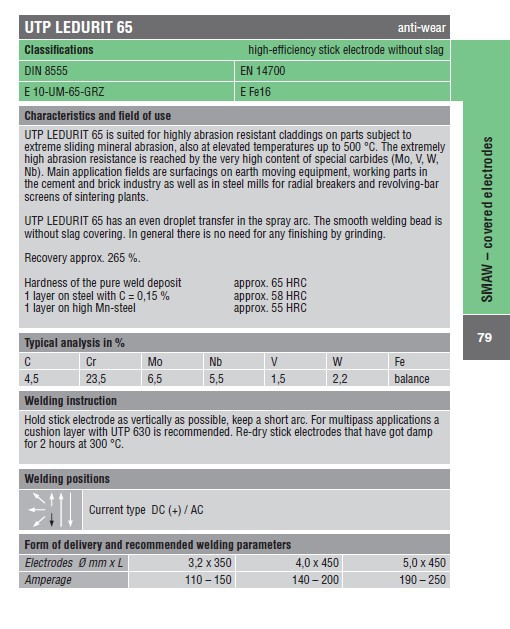

UTP LEDURIT 65 anti-wear

Classifications high-efficiency stick electrode without slag

DIN 8555 EN 14700

E 10-UM-65-GRZ E Fe16

Characteristics and field of use

UTP LEDURIT 65 is suited for highly abrasion resistant claddings on parts subject to

extreme sliding mineral abrasion, also at elevated temperatures up to 500 °C. The extremely

high abrasion resistance is reached by the very high content of special carbides (Mo, V, W,

Nb). Main application fields are surfacings on earth moving equipment, working parts in

the cement and brick industry as well as in steel mills for radial breakers and revolving-bar

screens of sintering plants.

UTP LEDURIT 65 has an even droplet transfer in the spray arc. The smooth welding bead is

without slag covering. In general there is no need for any finishing by grinding.

Recovery approx. 265 %.

Hardness of the pure weld deposit approx. 65 HRC

1 layer on steel with C = 0,15 % approx. 58 HRC

1 layer on high Mn-steel approx. 55 HRC

Typical analysis in %

C Cr Mo Nb V W Fe

4,5 23,5 6,5 5,5 1,5 2,2 balance

Welding instruction

Hold stick electrode as vertically as possible, keep a short arc. For multipass applications a

cushion layer with UTP 630 is recommended. Re-dry stick electrodes that have got damp

for 2 hours at 300 °C.

Welding positions

Current type DC (+) / AC

Form of delivery and recommended welding parameters

Electrodes Ø mm x L 3,2 x 350 4,0 x 450 5,0 x 450

Amperage 110 – 150 140 – 200 190 – 250

|

![]() 暂无相关下载

暂无相关下载