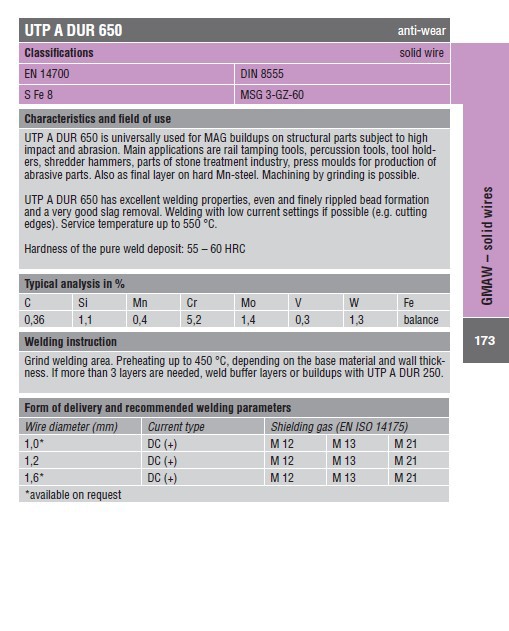

UTP A DUR 650 anti-wear

Classifications solid wire

EN 14700 DIN 8555

S Fe 8 MSG 3-GZ-60

Characteristics and field of use

UTP A DUR 650 is universally used for MAG buildups on structural parts subject to high

impact and abrasion. Main applications are rail tamping tools, percussion tools, tool holders,

shredder hammers, parts of stone treatment industry, press moulds for production of

abrasive parts. Also as final layer on hard Mn-steel. Machining by grinding is possible.

UTP A DUR 650 has excellent welding properties, even and finely rippled bead formation

and a very good slag removal. Welding with low current settings if possible (e.g. cutting

edges). Service temperature up to 550 °C.

Hardness of the pure weld deposit: 55 – 60 HRC

Typical analysis in %

C Si Mn Cr Mo V W Fe

0,36 1,1 0,4 5,2 1,4 0,3 1,3 balance

Welding instruction

Grind welding area. Preheating up to 450 °C, depending on the base material and wall thickness.

If more than 3 layers are needed, weld buffer layers or buildups with UTP A DUR 250.

Form of delivery and recommended welding parameters

Wire diameter (mm) Current type Shielding gas (EN ISO 14175)

1,0* DC (+) M 12 M 13 M 21

1,2 DC (+) M 12 M 13 M 21

1,6* DC (+) M 12 M 13 M 21

![]() 暂无相关下载

暂无相关下载