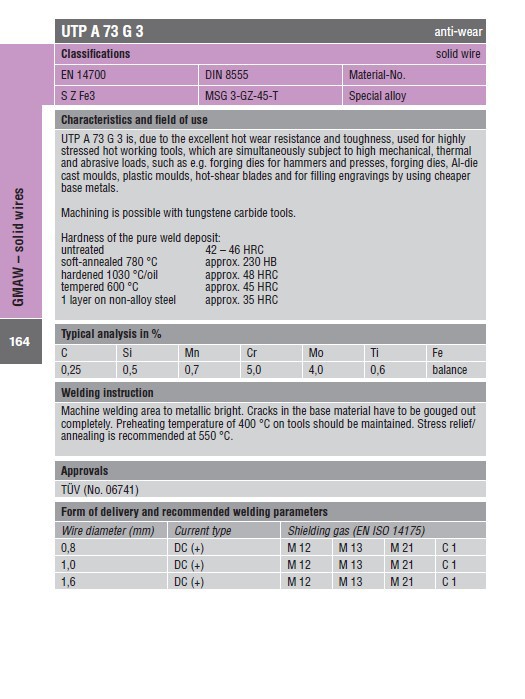

UTP A 73 G 3 anti-wear

Classifications solid wire

EN 14700 DIN 8555 Material-No.

S Z Fe3 MSG 3-GZ-45-T Special alloy

Characteristics and field of use

UTP A 73 G 3 is, due to the excellent hot wear resistance and toughness, used for highly

stressed hot working tools, which are simultaneously subject to high mechanical, thermal

and abrasive loads, such as e.g. forging dies for hammers and presses, forging dies, Al-die

cast moulds, plastic moulds, hot-shear blades and for filling engravings by using cheaper

base metals.

Machining is possible with tungstene carbide tools.

Hardness of the pure weld deposit:

untreated 42 – 46 HRC

soft-annealed 780 °C approx. 230 HB

hardened 1030 °C/oil approx. 48 HRC

tempered 600 °C approx. 45 HRC

1 layer on non-alloy steel approx. 35 HRC

Typical analysis in %

C Si Mn Cr Mo Ti Fe

0,25 0,5 0,7 5,0 4,0 0,6 balance

Welding instruction

Machine welding area to metallic bright. Cracks in the base material have to be gouged out

completely. Preheating temperature of 400 °C on tools should be maintained. Stress relief/

annealing is recommended at 550 °C.

Approvals

TÜV (No. 06741)

Form of delivery and recommended welding parameters

Wire diameter (mm) Current type Shielding gas (EN ISO 14175)

0,8 DC (+) M 12 M 13 M 21 C 1

1,0 DC (+) M 12 M 13 M 21 C 1

1,6 DC (+) M 12 M 13 M 21 C 1

![]() 暂无相关下载

暂无相关下载