| 详细介绍:

备注:一口价为1公斤的价格!20公斤/箱!

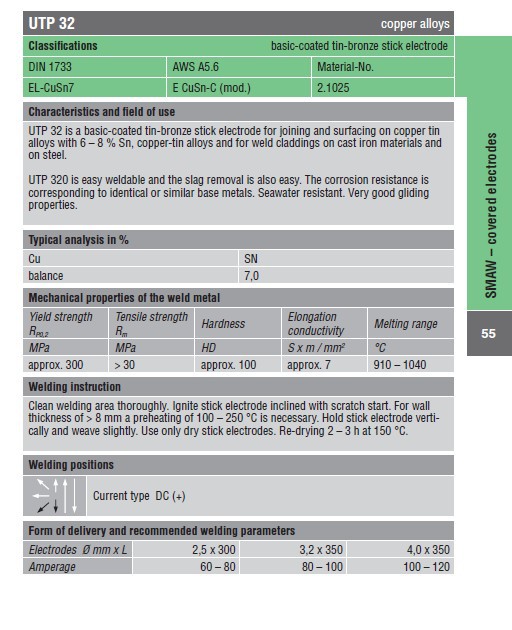

UTP 32 copper alloys

Classifications basic-coated tin-bronze stick electrode

DIN 1733 AWS A5.6 Material-No.

EL-CuSn7 E CuSn-C (mod.) 2.1025

Characteristics and field of use

UTP 32 is a basic-coated tin-bronze stick electrode for joining and surfacing on copper tin

alloys with 6 – 8 % Sn, copper-tin alloys and for weld claddings on cast iron materials and

on steel.

UTP 320 is easy weldable and the slag removal is also easy. The corrosion resistance is

corresponding to identical or similar base metals. Seawater resistant. Very good gliding

properties.

Typical analysis in %

Cu SN

balance 7,0

Mechanical properties of the weld metal

Yield strength

RP0,2

Tensile strength

Rm

Hardness Elongation

conductivity Melting range

MPa MPa HD S x m / mm2 °C

approx. 300 > 30 approx. 100 approx. 7 910 – 1040

Welding instruction

Clean welding area thoroughly. Ignite stick electrode inclined with scratch start. For wall

thickness of > 8 mm a preheating of 100 – 250 °C is necessary. Hold stick electrode vertically

and weave slightly. Use only dry stick electrodes. Re-drying 2 – 3 h at 150 °C.

Welding positions

Current type DC (+)

Form of delivery and recommended welding parameters

Electrodes Ø mm x L 2,5 x 300 3,2 x 350 4,0 x 350

Amperage 60 – 80 80 – 100 100 – 120

|

![]() 暂无相关下载

暂无相关下载