| 详细介绍:

备注:一口价为1公斤的价格!20公斤/箱!

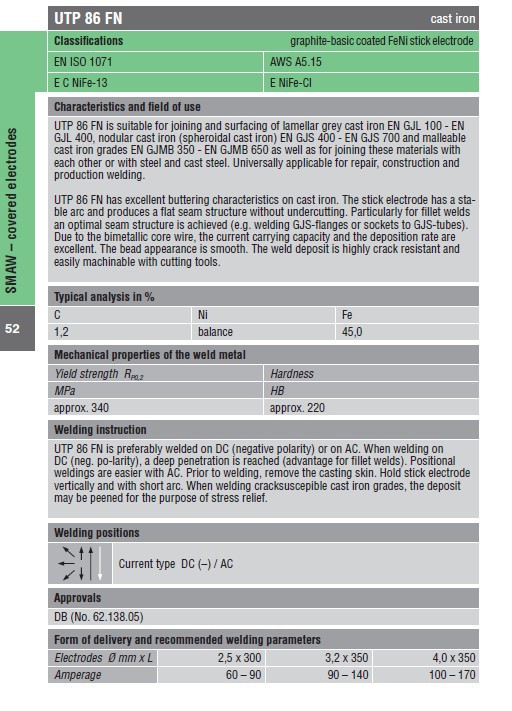

UTP 86 FN cast iron

Classifications graphite-basic coated FeNi stick electrode

EN ISO 1071 AWS A5.15

E C NiFe-13 E NiFe-Cl

Characteristics and field of use

UTP 86 FN is suitable for joining and surfacing of lamellar grey cast iron EN GJL 100 - EN

GJL 400, nodular cast iron (spheroidal cast iron) EN GJS 400 - EN GJS 700 and malleable

cast iron grades EN GJMB 350 - EN GJMB 650 as well as for joining these materials with

each other or with steel and cast steel. Universally applicable for repair, construction and

production welding.

UTP 86 FN has excellent buttering characteristics on cast iron. The stick electrode has a stable

arc and produces a flat seam structure without undercutting. Particularly for fillet welds

an optimal seam structure is achieved (e.g. welding GJS-flanges or sockets to GJS-tubes).

Due to the bimetallic core wire, the current carrying capacity and the deposition rate are

excellent. The bead appearance is smooth. The weld deposit is highly crack resistant and

easily machinable with cutting tools.

Typical analysis in %

C Ni Fe

1,2 balance 45,0

Mechanical properties of the weld metal

Yield strength RP0,2 Hardness

MPa HB

approx. 340 approx. 220

Welding instruction

UTP 86 FN is preferably welded on DC (negative polarity) or on AC. When welding on

DC (neg. po-larity), a deep penetration is reached (advantage for fillet welds). Positional

weldings are easier with AC. Prior to welding, remove the casting skin. Hold stick electrode

vertically and with short arc. When welding cracksuscepible cast iron grades, the deposit

may be peened for the purpose of stress relief.

Welding positions

Current type DC (–) / AC

Approvals

DB (No. 62.138.05)

Form of delivery and recommended welding parameters

Electrodes Ø mm x L 2,5 x 300 3,2 x 350 4,0 x 350

Amperage 60 – 90 90 – 140 100 – 170

|

![]() 暂无相关下载

暂无相关下载