商铺名称:山西万泽锦达机械制造有限公司

联系人:金志鹏(先生)

联系手机:

固定电话:

企业邮箱:2932089696@qq.com

联系地址:太原市小店区208国道东蒲村东浦路一号

邮编:

联系我时,请说是在五金机电网上看到的,谢谢!

商品详情

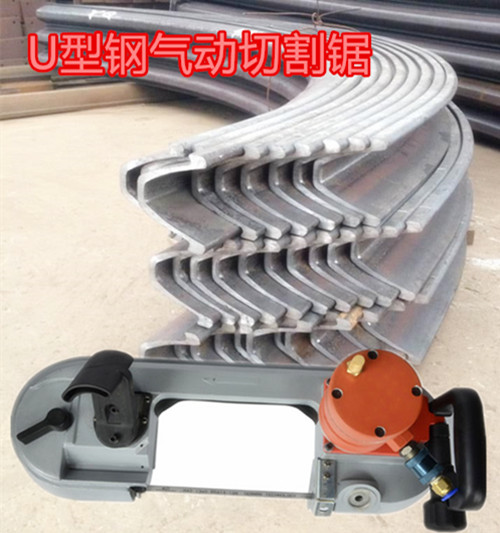

内蒙古呼伦贝尔往复式回转小锯床广东茂名硬材料小锯床广东珠海往复式回转风动锯内蒙古乌兰察布钢材风动锯湖南常宁电动小锯床 【FDJ切割锯】(切割锯、锚索切割锯、马刀锯、往复锯、台湾小锯床、带锯、切管锯、锯管机) 简介:万泽锦达FDJ切割锯是手持式便携切割工具。有风动切割锯和电动切割锯两款。由于切割速度快、无火花产生、轻巧便携操作,

深得广大用户的亲睐。 公司名称:山西万泽锦达机械制造有限公司

联系人金志鹏;电话13934240041 微信;j753565455

(切割锯、锚索切割锯、马刀锯、往复锯、台湾小锯床、带锯、切管锯、锯管机)规格参数: 型号 FDJ-120、FDJ-200 功率 3kw 重量 5.5kg 锯身材质 不锈钢 锯条材质 含钴高速工具钢 锯路 220mm 锯深 180mm 齿距 0.2mm 锯条厚度 0.1mm【切割材料及适用范围】 (切割锯、锚索切割锯、马刀锯、往复锯、台湾小锯床、带锯、切管锯、锯管机) 铁管、钢筋、电缆、铜管、铁棒、铜棒、锚杆、锚索、钢筋网、工字钢、槽钢、U型钢、H钢、角钢、矿工钢、轨道钢、C型钢。 主要适用于:矿井掘进支护、隧道掘进支护、边坡锚喷支护、地铁施工、桥梁施工、钢筋拆除回收、化工治炼厂、天然气开采、高危潮湿的隧道、水下及狭窄的空间作业 (切割锯、锚索切割锯、马刀锯、往复锯、台湾小锯床、带锯、切管锯、锯管机)特点: 无火花:切割不产生火花,安全防爆,特别适合矿井等高瓦斯区域作业 耐高温:采用含钴高速工具钢,使得锯条可以较长时间切割,不会因高温而使切割效果下降。 机动性强:重量轻、体积小使得单人操作游刃有余。 结构简单:拆装维修比较方便。 为了安全作业需要注意以下几点: 1、用锯的重量来控制切割压力。对于较软的材料来说,这样的重量已经足够。过多的压力会降低锯片的速度。对于较硬的材料,可以通过加压的方式来降低锯片的转动速度。切割是保持锯笔直。锯片的任何扭曲或歪斜都可能降低其使用寿命 2、关闭空气马达时,释放阀杆。 3、更换锯片前,务必断开空气软管,并推动阀杆以释放掉马达内的压力。 4、顺时针转动调整手柄以便释放锯片导杆上的张力。然后释放侧面板的锁以便打开侧面板。然后从驱动轮上取下锯片并将其从锯带导杆上松开。 5、下次切割开始前,锯片必须保持运动状态。气动锯时,锯片不能接触任何表面。 6、了解所需切割的材料,如有必要可以通过降低空气压力来降低锯片的转动速度。 7、确保牢固固定了所需切割的材料,防止其移动。 8、气动空气马达时,用手指按压阀杆,然后开始切割。 9、断开空气软管时,关闭空气软管阀。断开前,先打开空气阀给软管减压。

(cutting saw, cable cutting saw, horse knife saw, reciprocating saw, Taiwan small saw machine, band saw, sawing, sawing machine) specification parameters: Model FDJ-120, FDJ-200 Power 3kw Weight 5.5kg Sawing stainless steel Saw blade material with cobalt high speed tool steel Sawing 220mm Sawing 180mm Tooth distance 0.2mm Saw blade thickness 0.1mm [cutting materials and scope of application] (cutting saw, anchorage cut saw, horse knife saw, reciprocating saw, Taiwan small saw, band saw, sawing, sawing machine) Iron, steel, copper, iron, copper, cable, anchor, steel mesh, I-beam, channel steel, U steel, H steel, steel, steel, steel, coal miners C steel rail. Mainly applies to: mine excavation support, tunnel excavation and supporting, slope shotcreting support, subway construction, bridge construction, steel, chemical, dismantling and recycling refinery gas exploitation, high wet tunnel, underwater and narrow space operation (cutting saw, anchorage cutting saw, horse knife saw, reciprocating saw, Taiwan small saw, band saw, sawing, sawing machine): No spark: cutting does not produce sparks, safety and explosion-proof, especially suitable for mine and other high gas area operation High temperature resistance: the use of cobalt high speed tool steel makes the saw blade cut for a long time, and the cutting effect will not be reduced because of the high temperature. Strong maneuverability: light weight and small volume make it easy for single person to operate. The structure is simple: it is convenient to disassemble and repair. In order to work safely, we need to pay attention to the following points: 1, use the weight of the saw to control the cutting pressure. This weight is enough for softer materials. Too much pressure can reduce the speed of the saw blade. For harder materials, the speed of rotation of the saw blade can be reduced by pressure. The cutting is to keep the saws straight. Any twist or skew of the sawblade may reduce its service life 2. When the air motor is closed, the stem is released. 3. Before replacing the saw, be sure to disconnect the air hose and push the stem to release the pressure of Madane. 4, adjust the handle clockwise to release the tension on the sawing guide rod. Then release the lock of the side panel so as to open the side panel. Then remove the blade from the drive wheel and release it from the sawing guide rod. 5. The saw blade must remain moving before the next cutting begins. The saw blade can't contact any surface when a pneumatic saw. 6, understand the material needed to cut, if necessary to reduce the speed of rotation of the saw blade by reducing the pressure of the air. 7, ensure that the required cutting material is firmly fixed to prevent its movement. 8. When pneumatic air motor is operated, the stem is pressed with the finger, and then the cutting is started. 9. When the air hose is disconnected, the air hose valve is closed. Before disconnecting, open the air valve and decompress the hose.

在线询盘/留言