商铺名称:桂林山禾机电有限公司

联系人:王涛(先生)

联系手机:

固定电话:

企业邮箱:13557662230@163.com

联系地址:广西桂林市临桂区金水路3号

邮编:541100

联系我时,请说是在五金机电网上看到的,谢谢!

- Non-Stick, abrasion resistant properties

- Substantially reduces friction

- Corrosion resistant

- Lubricious

- Water-based, environmentally friendly

- Safe and easy to apply

- Cures at room temperature

- Superior surface protection in fresh and salt water environments

- Durable

- Surfaces stay clean, reducing maintenance costs

- Clean up with water

- Waterproof in a cured state

- Apply with conventional equipment

- Extends the life of steel, iron, aluminum, concrete, and a wide range of other substrates

-

Stretch Forming aluminum for the auto and aircraft industry (Wearlon 2020.98-Hybrid) – per Boeing “Supplier Communication,” Issue 48, July 2001, Wearlon:

- Reduces cycle time and saves labor costs

- Eliminates oil and solvent, as well as hazardous material disposal

- Increases wear characteristics to prolong the life of the tools

- Reduces / eliminates variation due to oil viscosity and usage

- Eliminates oxidation of aluminum and plastic dies

- Reduces tooling hour on new makes and re-cuts by reducing the benching (sanding) operations.

-

Improved cutting for:

- Lawn mower blades

- Rototiller blades

- Circular saw blades

- Band saw blades

- Razor blades

- Extended life of cutting blades

- 40% reduction of measured amperage on coated circular saw blades

- Wearlon 2020.98 has excellent release as a coating on rolls as demonstrated above.

- Wearlon 2020.98 excelled when compared to Dupont 954-203 and Dupont 532-8110 upon monitoring the release force at the start and after 4 weeks immersion in sulphate pulp at 194°F. This test is labeled CWSP test (Concentrated Water Sulphate Pulp test). Concentrated water from sulphate pulp was prepared by removing fibers from sulphate pulp. The volume of the water was decreased in half by evaporation.

- Wearlon 2020.98 maintained consistently lower release when compared to Xylan 1010, Dupont 958-203, Dupont 958-406, and Dupont 958-414 after two and four weeks immersion in TMP (Thermal Mechanical Pulp) at 86°F.

- Wearlon 2020.98 release force remained lower than Xylan 1010, Dupont 958-203, Dupont 958-406, and Dupont 958-414 when immersed in 10% sulphuric acid for 24 hours at room temperature.

- Immersion for 24 hours in a temperature of 194°F in caustic baths of 10% and 40% sodium hydroxide indicated the following. The 40% sodium hydroxide was not as detrimental to the Wearlon 2020.98 as the 10% solution was. The Dupont 958-203 performed better in this test. Xylan 1010, Dupont 958-406, and Dupont 958-414 were washed away in the 40% sodium hydroxide test. The Wearlon 2020.98 release force was increased from 50N to 70N after 6.5 hours in the 10% sodium hydroxide bath.

- Heat aging at 221°F for four weeks reduced the release force of the Wearlon 2020.98.

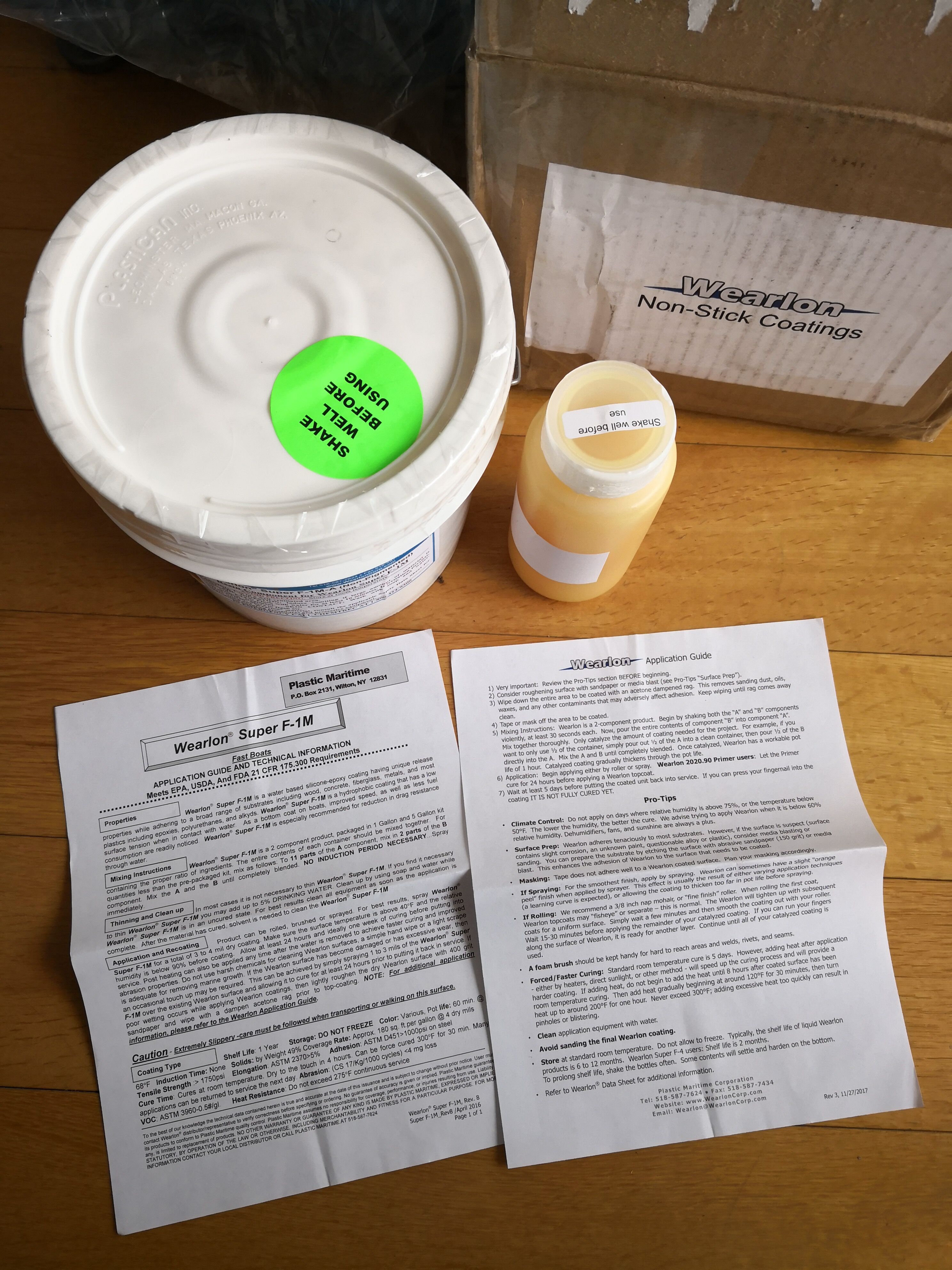

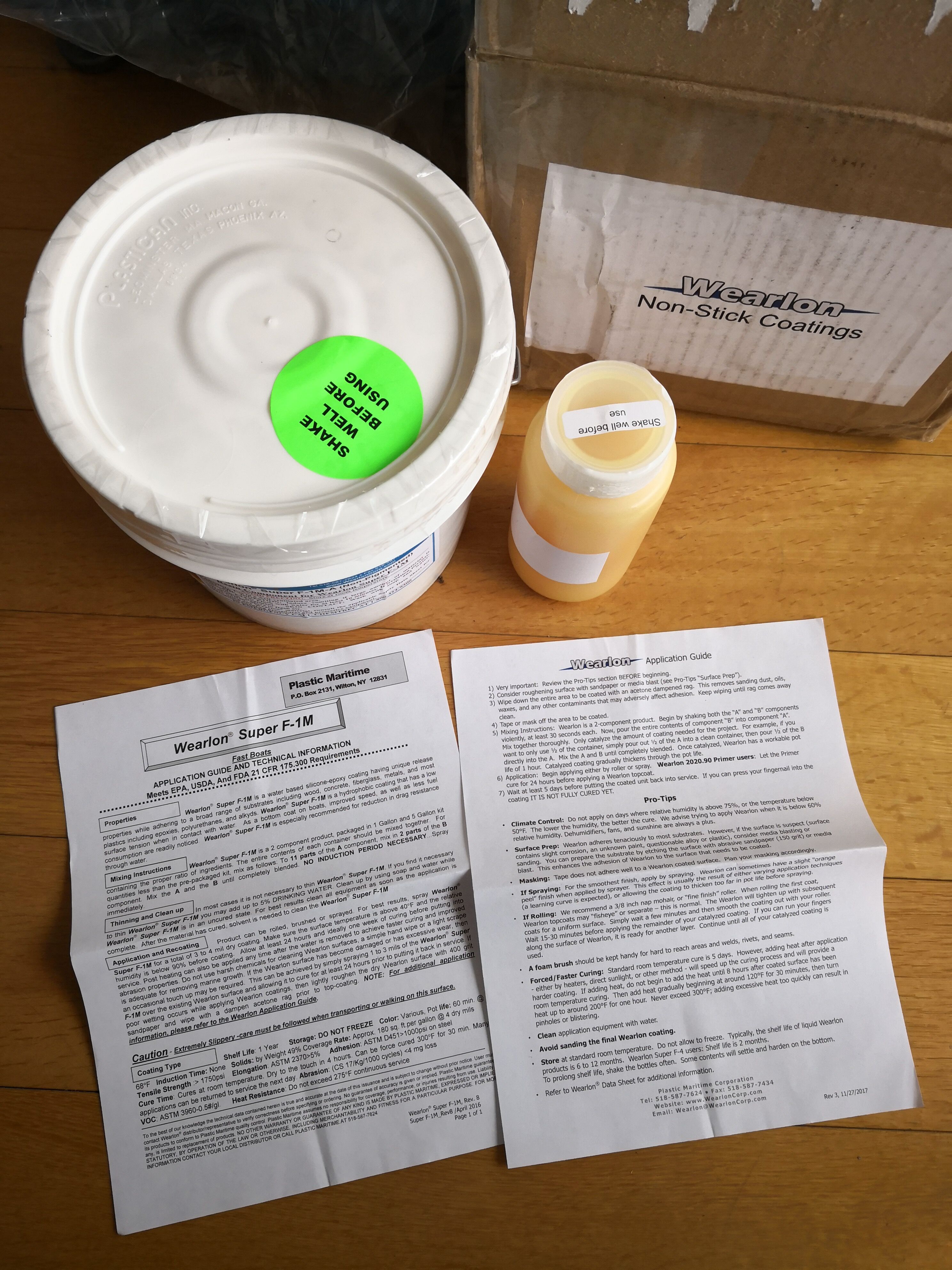

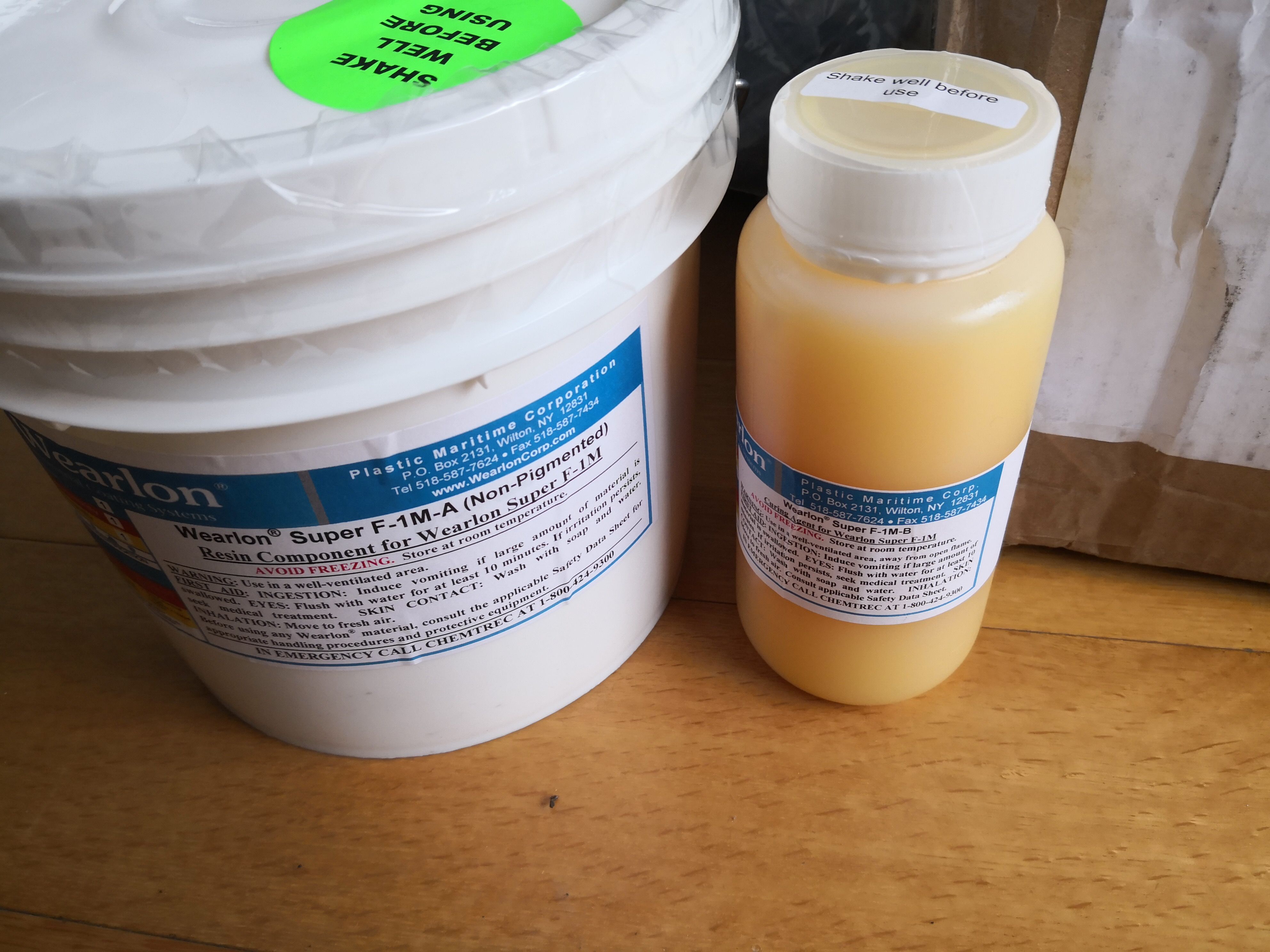

美国wearlon防冰涂料Wearlon? 2020.98

桂林山禾机电有限公司一级优势代理 美国wearlon防冰涂料全系列产品。

具有货期和价格优势!常用产品常备有库存。质量保证,原装正品,假一罚十,欢迎咨询洽谈。

,真诚期待与您的合作!

桂林山禾机电有限公司具有货期和价格优势!常用产品常备有库存。质量保证,原装正品,假一罚十,欢迎咨询洽谈。

,真诚期待与您的合作!

如您对美国道康宁Dow Corning润滑脂系列产品感兴趣,详情来电咨询!

联系人:王涛;联系电话:135-5766-2230

Email:13557662230@163.com;QQ号码:3133954024

桂林山禾机电有限公司以诚信为本,只做全新原装正品。代理品牌有:

美国道康宁Dow Corning润滑脂、美国摩力克MOLYKOTE润滑脂、美国洁普zep、美国COLTOFLAX密封剂、日本SOLVEST油脂、日本Earth-tech株式会社LUBROID超极压润滑剂、日本sunhayato清洗剂、maruiマルイ鍍金工業、美国GOJO(戈乔)清洗剂、JX日矿日石(原新日本石油)润滑油、日本STJ 清洗剂、铃木油脂工业(SYK)、东洋化学商会 (TOYO)、日本山本CHEMICAL-Y清洗剂、日本大造DAIZO润滑剂、东亚合成TOAGOSEI胶水、日本R-GOT/BASARA 切削油、美国Devcon(得复康)胶水、日本NIHON HERMETICS 管道密封胶、日本ABC商会润滑剂、法国Bostik波士胶润滑剂、日本TASETO润滑剂、日本住友3M清洗剂、日本施敏打硬CEMEDINE胶水、日本东洋toyo-safety清洗剂、日本Loctite乐泰胶水、日本中山TRUSCO清洗剂、日本益冉化学ichinen清洗剂、道康宁molykote摩力克润滑油、日本NOK润滑剂 KLUEBER、日本MOMENTIVE迈图(原GE东芝)硅胶、日本吴工业KURE清洗剂、日本BOND小西KONISHI,胶水、日本SUMICO住矿润滑剂、日本信越化学ShinEtsu密封剂、美国太阳PERMATEX胶水、日本threebond三键密封剂、日本友和YUWA清洗剂、日本早川HRC防水密封胶、日本ROCK PAINT涂料清洗剂、日本YANASEヤナセ制油润滑剂、日本中京化成清洗剂、中京研磨(CHUKYO KENMA,研磨剂、NICHIMOLY/DAIZO北山化学润滑脂、日本FCJ润滑剂、日本DNT大日本塗料胶水、日本SOMAY-Q 染めQ胶水等产品

桂林山禾机电有限公司主营日本、欧美、韩国、台湾机电工业产品和化学品,

桂林山禾机电有限公司;联系人:王涛;联系电话:135-5766-2230

Email:13557662230@163.com;QQ号码:3133954024

桂林山禾机电有限公司致力于向客户提供世界一流的机电工业用品、化学用品、工业电气自动化产品;代理销售日本和欧美各大品牌机电工业产品和化学产品,主要代理和经销品牌有:

日本日东工业NITO、日本KIMDEN指示灯、河村电器KAWAMURA、日本光商工HIKARISHOKO、三桂制作所SANKEI、日本SUS配电产品、日本SEIKO正兴继电器、日本帕斯卡PASCAL、磐田电工株式会社(IWATA DENKO)、中兴化成CHUKOH、日本和泉IDEC、日本欧姆龙OMRON、日本三菱电机、日本富士电机、CKD、SMC、油研YUKEN、松下电器、韩国凯昆、山一化学、日本WASINO流量计、日本瓜生(URYU)工具、日本井口机工(ISB)、德国爱姆卡EMKA,日本maruyasu丸安指示灯、日本NICHIAS霓佳斯、日本高柳(TRINC)静电除尘装置日本新机械(NEW MACHINE)接头、日本YOSHIDA吉田电机、日本kanaflex、日本KOKUSAI DENGYO国际电业脚踏开关、TOCHIGIYA栃木屋、日本住友重机SUMITOMO减速机、日本OPTEX FA光电传感器、日本福田电机变压器、日本井原IFARA接头、日本第一电子工业DDK连接器、小柳机工oyanagikiko、日本ABC台东研磨工业油石、日本TAJIMI多治见连接器、长野计器NKS、第一计器DAIICHI KEIKI压力表、日本航空电子工业JAE连接器、日本JEFCOM 连接器、山本电机MANOSTAR微差压计、日本FCJ润滑剂、日本DNT大日本塗料胶水等公司产品。

桂林山禾机电有限公司;联系人:王涛;联系电话:135-5766-2230

Email:13557662230@163.com;QQ号码:3133954024

Wearlon® 2020.98

Lowest "Coefficient Of Friction" Wearlon Product

ADVANTAGESAs a lubricious, friction-reducingcoating, Wearlon® 2020.98 providesprotection of heat built-up and subsequent material distortion, or damage. This translates into an ideal life-extending coating material for saw blades, rollers, and a host of tool, industrial, and sporting equipmentapplications. |

|

Wearlon® 2020.98 - Slip Properties

(Low Coefficient of Friction)

ADVANTAGES |

|

Wearlon 2020.98 - Cutting Tools

|

ADVANTAGES |

|

Extensive testing at the University of Oulu in Finland demonstrated the excellent performance properties of Wearlon 2020.98 in the paper and converting industries.

University of Oulu, Finland Fibre and Particle Engineering Laboratory Department of Process and Environmental Engineering

Measurement of nonstick property

The nonstick property of different coatings was measured with tape release test. The method is modified from TAPPI UM 502 using ABgene PCR adhesive film 0558 (Applied Biosystems Corp.) The test tape is attached to surface and then peeled off 180° angle at 1 inch/min speed. Required force was measured. Before every measurement surface was cleaned and temperature was measured.

Release properties of test roller

Roller was first coated with tungsten carbide and then with different nonstick coatings. Nonstick properties of these coatings were measured with tape release test.